Whole House Repiping Services: Cost, Process, and Benefits for Homeowners and Businesses

Whole house repiping replaces a building’s internal water-delivery system—supply lines, fittings, valves, and manifolds—with new piping to restore clean water, steady pressure, and dependable performance. Below we explain what a full repipe involves, why it matters for homeowners and property managers, and how common material choices like PEX or copper affect durability and cost. You’ll learn the warning signs of system-wide pipe failure, the typical repipe workflow from inspection through cleanup, material comparisons, and financing options that make a major job manageable. Practical checklists and step-by-step guidance help you decide whether a full repipe is right for your home or business, with local context for Tomball and nearby Texas communities and clear next steps to schedule an inspection.

What Are the Signs You Need Whole House Repiping?

We usually recommend whole house repiping when the problems point to the entire distribution system, not just a single fixture. Catching a failing system early reduces water damage and health risks. Look for consistent, system-wide symptoms: low or fluctuating pressure, rusty or metallic-tasting water, repeated leaks, noisy pipes, or an old galvanized system showing its age. Each sign points to a mechanism—corrosion and mineral buildup narrow pipes, while failing joints and pinhole leaks raise the chance of damage. Spotting these patterns helps you choose a lasting solution instead of band-aid repairs. Use the checklist below to self-assess and to describe issues clearly during a professional inspection.

Common signs that indicate a whole house repipe is needed:

- Low or inconsistent water pressure in multiple fixtures: Pressure loss at several outlets usually means reduced internal diameter from scale or widespread corrosion, not a single clogged aerator.

- Discolored, rusty, or metallic-tasting water: Ongoing discoloration or taste issues point to internal pipe corrosion or sediment getting into the water.

- Frequent leaks or recurring pipe repairs: Patching leaks in many locations is a strong clue the system is failing and will keep needing work.

- Noisy pipes, banging, or constant water hammer: Persistent sounds often signal loose fittings or internal deterioration across the network.

- Older homes with galvanized pipe networks: Galvanized systems commonly corrode over decades and are prone to leaks and contamination.

These clues usually mean the problem is system-level, so the next step is a targeted inspection to confirm pipe condition and scope. From there you can decide whether a full repipe, a section replacement, or a filtration solution best fits your property.

How Does Low Water Pressure Indicate Pipe Problems?

When several fixtures lose pressure at once, the issue is often throughout the distribution system rather than at one valve or faucet. Common causes include internal corrosion, mineral scale, or partial blockages that reduce the pipe’s effective diameter. You can check whether low pressure is isolated or system-wide by running multiple fixtures at the same time and checking flow at the main shutoff; if several outlets show reduced flow, the supply network is the likely culprit. A pro can confirm with pressure gauges and visual inspection where accessible. If pipe degradation is the cause, repiping restores full internal diameter, improves flow, and brings pressure back to expected levels.

What Are the Effects of Discolored Water and Frequent Leaks?

Discolored water and recurring leaks are classic signs of internal corrosion and failing joints. Rust-colored water usually means iron corrosion inside older metal pipes; a metallic taste can indicate elevated metal levels that deserve quick attention. Repeated leaks add up—stains, rot, and hidden mold can make remediation far more expensive than the plumbing work itself. Replacing the whole distribution system removes the corroded material, eliminates frequent failure points, and cuts long-term maintenance. Many homeowners follow a repipe with water filtration or a water heater tune-up to optimize overall water quality and appliance performance.

How Much Does Whole House Repiping Cost?

Costs for a whole house repipe vary widely depending on home size, chosen materials (PEX vs. copper), accessibility, fixture count, and the extent of finish repairs. For single-family homes this typically ranges from mid-to-high four figures up to low five figures. Major cost drivers include labor, drywall or flooring restoration, permit and inspection fees, and complex routing such as slab penetrations. Understanding these factors helps you compare options like partial repipes, slab-focused repairs, or a full-system replacement. The list below summarizes the primary cost influencers so you can quickly see which apply to your property before scheduling an estimate.

Primary factors that affect repiping project scope and budget:

- Home size and number of plumbing fixtures: More footage and fixtures means more materials and labor time.

- Piping material choice: Copper usually costs more in both materials and installation than PEX, which affects the upfront price.

- Accessibility and routing complexity: Slab work, multiple floors, or tight crawlspaces raise labor and restoration needs.

- Finish repairs and restoration: Drywall, cabinetry, flooring, and paint work to close chases add to the final invoice.

- Local permits and inspections: Municipal requirements and code compliance affect timeline and cost.

Knowing how each factor changes the project helps you budget. A professional inspection gives the precise scope and a realistic timeline for your home.

Intro to the cost factor table: The table below breaks common cost drivers into clear attributes and typical impacts so you can quickly scan what matters when estimating repipe scope.

| Factor | Attribute | Typical Range / Example |

|---|---|---|

| Home size & fixtures | Labor & material scale | Small homes: lower end; large homes: substantially higher |

| Material choice | Cost per linear foot & fittings | PEX: lower material and install time; copper: higher material/labor |

| Accessibility | Time to access/route pipes | Slab access or multi-story routing increases time and cost |

| Restoration needs | Drywall, painting, cabinetry repairs | Minor patching to major finishes add to final invoice |

| Permits & inspections | Administrative and compliance costs | Varies by municipality; must budget for local requirements |

What Factors Affect the Cost of Repiping Your Home?

The repipe cost equation combines material, labor, and finish work. Harder access raises labor hours, which magnifies the effect of material choice on total cost. For example, copper costs more upfront, but in some cases its longevity or perceived resale value can justify the price. Slab penetrations and tight crawlspaces multiply labor; homes with many fixtures need extra manifolds and fittings. Permit and inspection fees vary by city and should be included in your budget. Ask your contractor for a detailed quote that splits material, labor, and restoration so you see where choices save—or add—you money.

What Is the Average Cost for Galvanized Pipe Replacement?

Replacing galvanized pipe often requires more work than swapping recent copper or PEX because corroded galvanized can flake, stick to fittings, and reveal hidden damage behind walls or under floors. That increases labor and finish-repair needs. Galvanized replacements generally sit at the higher end of repipe budgets for similarly sized homes due to cleanup and potential remediation like fixture replacement or lead testing. Plan for contingencies when dealing with galvanized systems and include water-quality testing as part of the inspection. Good documentation at inspection helps decide where full replacement is necessary versus spot remediation.

PEX vs. Copper Repiping: Which Material Is Best for Your Home?

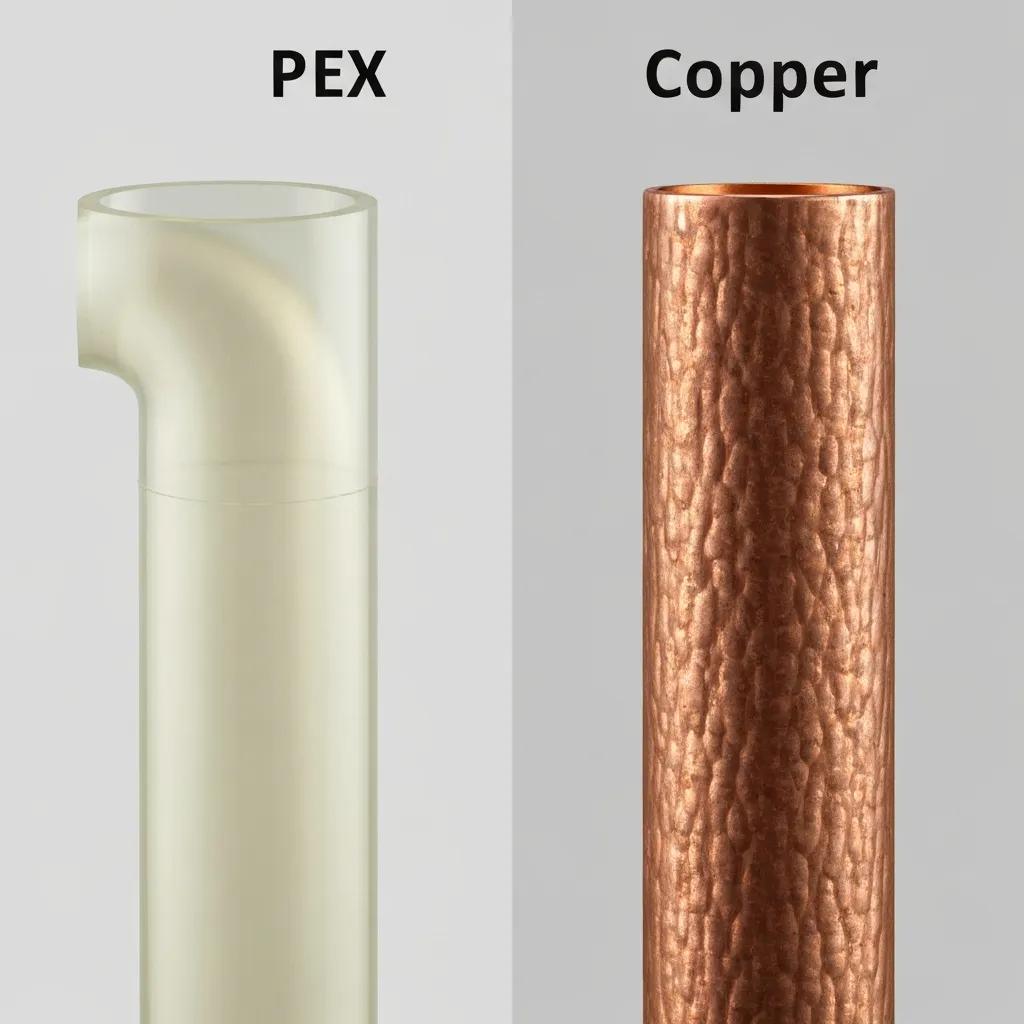

Choosing between PEX and copper comes down to priorities: upfront cost, lifespan, freeze resistance, and installation disruption. PEX is flexible, installs faster, and resists scale and pinhole corrosion—making it a popular retrofit choice and a good option where freeze protection is important when installed to code. Copper has a long track record, high heat tolerance, and strong resale perception, but usually costs more and takes longer to install. The table below compares cost, lifespan, freeze resistance, corrosion behavior, installation time, and common use cases to help you decide what fits your home and local climate.

Table introduction: The comparison below summarizes material attributes to inform homeowner decisions between PEX and copper.

| Material | Characteristic | Typical Value / Impact |

|---|---|---|

| PEX | Cost & installation | Lower material cost; faster install with fewer fittings |

| PEX | Lifespan | 25–50 years depending on quality and exposure |

| PEX | Freeze resistance | Flexible; better at resisting bursts from freezing when properly installed |

| Copper | Durability | 50+ years in many cases; proven long-term performance |

| Copper | Corrosion profile | Can corrode in aggressive water conditions; visible signs may appear |

| Copper | Installation | Requires soldering or mechanical fittings; generally slower to install |

What Are the Benefits and Drawbacks of PEX Repiping?

PEX brings several practical benefits: flexibility that reduces fittings, shorter install times, and lower material costs. Its flexibility also helps it tolerate freeze expansion better than rigid pipe in many cases. Downsides include sensitivity to UV light—so it must be protected during storage and installation—and code limitations in some areas that influence allowable fittings. Long-term performance depends on fitting type and local water chemistry. For many homeowners, PEX offers a cost-effective, low-disruption option when installed by professionals following manufacturer instructions and local code.

Choosing the Right Water Pipe Material: PEX, Copper, and Multilayer Options

Common water pipe choices include copper, multilayer, and PEX. When balancing price and performance, PEX often presents a favorable option. DETERMINING THE MOST SUITABLE MATERIAL FOR WATER PIPES, 2012

How Does Copper Repiping Compare in Durability and Cost?

Copper delivers long-term durability, excellent heat tolerance, and a proven track record in residential and commercial plumbing—traits that can support resale value and homeowner confidence. Copper resists many mechanical damages and performs well with high-temperature water, but it usually costs more and takes longer to install because of soldering and precise routing. In areas with aggressive water chemistry, copper may need water treatment to limit corrosion. When considering copper, weigh lifecycle value, local water quality, and how restoration scope affects the total investment.

PEX vs. Copper Plumbing: Environmental and Economic Life Cycle Assessment

A life-cycle assessment comparing PEX and copper plumbing systems found higher CO2-equivalent emissions and greater costs for copper compared with some alternatives. Environmental and economic life cycle assessment of PEX and copper plumbing systems: A case study, S Asadi, 2016

What Is the Whole House Repiping Process?

A typical repipe follows an ordered sequence: inspection and scoping, planning and permits, installation, testing and commissioning, then cleanup and restoration. That predictable flow helps homeowners plan for temporary water interruptions and access needs. The inspection confirms pipe materials, counts fixtures, checks for slab or crawlspace issues, and identifies finish-repair needs—information that shapes permits and material selection. Installation usually proceeds zone-by-zone to reduce disruption. After pressure testing and sanitization, finishes are restored and a final walkthrough verifies the work. The numbered list below outlines the usual workflow and what to expect during a 2–5 day repipe for many homes.

The whole house repiping steps:

- Inspection & diagnostics: Pressure testing, visual inspection, and fixture inventory define scope and material recommendations.

- Planning & permits: Material selection, routing plans, and municipal permit procurement are completed before work begins.

- Installation: Old piping is removed or capped per plan, and new piping is routed, connected, and secured.

- Testing & commissioning: Pressure tests, leak checks, and system sanitization verify integrity and water quality.

- Cleanup & restoration: Drywall patching, painting, and finish repairs are completed, followed by a final walkthrough.

This step-by-step approach minimizes surprises by combining diagnostics, code compliance, and finish work into one coordinated plan.

How Is the Initial Inspection and Planning Conducted?

Initial inspection mixes diagnostic checks—pressure testing, visual review of accessible piping, and fixture counts—with a conversation about recurring issues to create an accurate scope. Technicians record pipe materials (PEX, copper, galvanized), note slab penetrations or hard-to-reach areas, and flag appliances that might need concurrent work such as a water heater tune-up or filtration changes. The inspection report outlines recommended materials, restoration needs, and an estimated timeline for permits. Clearing access to mechanical rooms, crawlspaces, and attics before the visit helps speed the process. Good planning sets expectations for water interruptions and finish repairs that follow the physical repiping.

After inspection and planning, the focus turns to installing the new system efficiently while keeping disruption to a minimum and performing strong quality checks.

What Are the Installation Steps and Post-Installation Cleanup?

Installation starts by isolating water, removing or capping old lines as required, and running new piping according to the routing plan—usually zone-by-zone to limit downtime. Installers make connections at fixtures and manifolds, secure piping, and restore structural elements as work progresses. Pressure testing is done before fixtures are put back into service to catch leaks under load. Once tests pass, crews flush and sanitize the new lines and verify water clarity. Cleanup includes drywall patching, carpentry, and painting where chase access was needed, and a final walkthrough with the homeowner documents the work and provides operation tips. The goal is a safe, code-compliant system with documented verification that supports warranties and future maintenance.

Tradition Services provides local inspection and diagnostic services for homeowners in Tomball, Cypress, The Woodlands, and surrounding Texas communities. We translate inspection findings into a clear repiping plan with defined timeline milestones and restoration expectations. To schedule a site visit or discuss options, contact Tradition Services by phone at (346) 572-0600. Our process emphasizes clear communication and a customer-first approach to minimize disruption during repiping projects.

Frequently Asked Questions

What is the typical lifespan of PEX and copper pipes?

PEX typically lasts 25–50 years depending on product quality and conditions; it resists scale and corrosion well. Copper can last 50 years or more when water chemistry is favorable and the system is maintained. Your local water quality and installation details influence expected lifespan.

How can I prepare my home for a repiping project?

Prepare by clearing access to basements, crawlspaces, attics, and mechanical rooms. Move personal items away from work zones and let your contractor know any special concerns. Good communication and clear access speed the job and reduce disruption.

What should I expect during the repiping installation process?

Expect a staged, zone-by-zone installation: water isolation, removal or capping of old lines, and routing of new piping. Technicians perform pressure testing and sanitization before returning fixtures to service. Cleanup and finish repairs follow, and a final walkthrough confirms the work.

Are there any health risks associated with old plumbing systems?

Yes—old galvanized or lead-containing systems can leach metals, and corroded pipes can release sediment into water. Repeated leaks also create moisture issues that can encourage mold. Upgrading to modern piping and addressing water quality helps reduce these risks.

How does repiping affect my home’s resale value?

A documented repipe can boost buyer confidence by removing a common inspection concern. New plumbing lowers the chance of future repairs and can simplify disclosures, often making the property more attractive to buyers.

Whole-House Repiping: Costs, Process & Benefits for Property Owners

Whole house repiping restores water quality, steadies pressure, and improves long-term plumbing reliability—benefits that matter for everyday comfort and property value. If you see signs of system-wide pipe failure, schedule a professional inspection to review your options. Contact Tradition Services today to discuss an inspection or get a repipe plan tailored to your home.